Changer de langue :

0 lubrication, 0 costs, 0 worries: "GO ZERO"

What is "GO ZERO"?

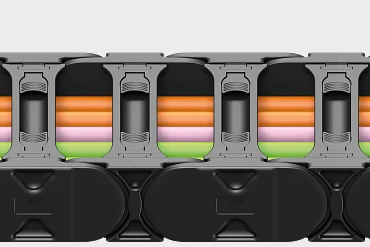

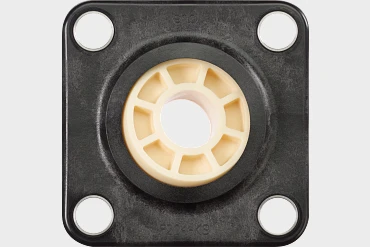

motion plastic are high-performance plastics that are used everywhere in industry - and no longer need to be lubricated by users after installation.

This means that not only are expensive greases and oils saved.

Customers also save on maintenance time, labour costs, the risk of incorrect or insufficient lubrication, system downtime and harmful substances that end up in the field or down the drain. We call this: "GO ZERO"

These 3 sectors are already benefiting from "GO ZERO"

Agricultural engineering

This saves Lemken 22 lubrication points per cultivator.

Construction machinery

This saves Huppenkothen 220 maintenance cycles per mini-excavator.

Beverage technology

This saves Heineken Brasil up to 28 tonnes of CO2-equivalent per year.

white paper: lubrication-free study of RWTH Aachen University and all use cases

In this white paper, we show which industries and companies are already successfully using lubrication- and maintenance-free bearing technology and the extent to which they benefit from the savings.

Including: Heineken Brasil (beverage technology), KettenWulf (drive and conveyor technology) and Rockinger (agricultural engineering).

Further topics:

- What does lubrication cost?

- Costs of lubrication for industry and the environment

- How do lubrication-free plain bearings work?

- Operating conditions of lubrication-free plain bearings

This saves Lemken 22 lubrication points per cultivator.

Lemken GmbH and Co. KG

... has specialised in the manufacture of agricultural equipment. This includes the Karat 9, an intensive cultivator with tines up to 30 centimetres long. To prevent the tool from being damaged, the tines deflect if too much force is applied - for example by stones in the soil.

The problem

Metal bearings were used on all of the tines to ensure the evasive movement. However, the metal bearings had to be lubricated for up to an hour every day. If this was not done, the lack of lubrication would have led to corrosion and wear.

The solution

The iglidur® bearings used today work completely without external lubrication, as the material contains self-lubricating solid lubricants. This not only saves the farmer time later on... He also benefits from the high force absorption of the bearing, its lower susceptibility to dirt and an increased downtime of the plain bearings.

What if ...

... every cultivator in Germany was converted to lubrication-free storage technology?

invert_colors_off

600.000 €

Saved lubricant costs

person

€2,397,940

Saved personnel costs

access_time

110,250 hrs.

Saved maintenance time

public

47,618 kg

CO saved2-equivalent

local_drink

2.600.000 l

Less contaminated freshwater due to pollutants

nature

19,268 ha

Less contaminated soil due to pollutant discharge

What lubrication-free potential still exists in the agricultural industry?

1 Cabin monitor adjustment

... with curved, lubrication-free rail guide in the tractor cab.

2 Clutch wear protection

... with lubrication-free insert on the trailer coupling.

3 Cable routing for field sprayer

... with robust energy chain for safe guidance of media in dusty and dirty conditions.

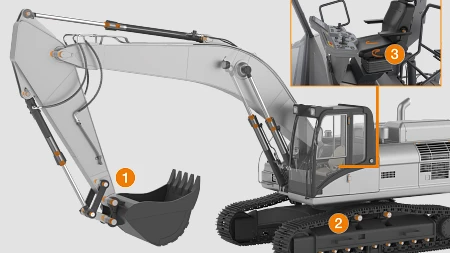

This saves Huppenkothen 220 maintenance cycles per mini-excavator per year.

Just four bearing points at the connection between the stick and excavator bucket, which are converted to lubrication-free polymer bearings, save the user 220 maintenance cycles and 36.7 hours of maintenance time per machine and per year.

The Huppenkothen GmbH

... is a supplier of compact excavators, mini excavators and other small equipment and construction vehicles.

The problem

In excavators, the bearing points between the stick and excavator bucket are exposed to high forces and harsh environmental influences. Steel bushings are often still used here, which have to be lubricated daily to ensure smooth and low-wear operation.

The solution

Four lubrication-free bearings made of high-performance polymer replace the metal bearings at the connection between the stick and bucket. This not only saves 220 maintenance operations per year, but also saves the user high costs for lubricating grease. The risk of insufficient or incorrect lubrication is also reduced.

What if ...

... every shovel excavator in Germany was converted to lubrication-free bearing technology?

invert_colors_off

€1,610,400

Saved lubricant costs

person

€14,607,520

Saved personnel costs

access_time

671,610 hrs.

Saved maintenance time

public

116,189 kg

CO saved2-equivalent

local_drink

2.600.000 l

Less contaminated freshwater due to pollutants

nature

19,268 ha

Less contaminated soil due to pollutant discharge

What other lubrication-free potential is there in construction machinery?

1 Bearings in the arm system

... e.g. with iglidur® G polymer bearings for the lubrication-free arm movement.

2 bearing points in the running gear

... with completely lubrication-free and maintenance-free high-load bearings made of fibre composite material.

3 Cable routing in the seat

... with robust and corrosion-free polymer energy chain for safe guidance of media.

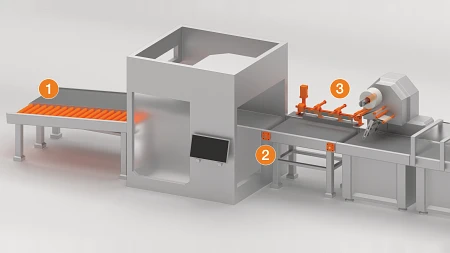

In this way, Heineken Brasil saves up to 28 tonnes of CO2 equivalent per year.

By replacing 600 radial bearings in the transport technology of a single Heineken branch, the Group is already saving 180 kgof CO2 equivalentper year.

Heineken Brasil

... is the Brazilian branch of a total of 160 branches of the world-famous brewery brand Heineken.

The problem

Modern bottling plants can fill up to 70,000 bottles per hour. This process requires a large number of moving parts, such as conveyor technology. Previously, Heinken Brasil had to regularly check and re-grease lubrication points on 600 radial bearings in the conveyor belt.

The solution

Polymer bearings are now used in conveyor technology. In future, these will no longer need to be lubricated or serviced during maintenance operations. This saves Heineken Brasil 1,560 hours of maintenance time per year and €2,815.49 in costs just for the lubricating greases saved.

What if ...

... every Heineken branch in conveyor technology used lubrication-free storage technology?

invert_colors_off

€450,478

Saved lubricant costs

person

€5,428,800

Saved personnel costs

access_time

249,600 hrs.

Saved maintenance time

public

28,814 kg

CO saved2-equivalent

local_drink

75.000.000 l

Less contaminated freshwater due to pollutants

nature

546,500 ha

Less contaminated soil due to pollutant discharge

What lubrication-free potential is still available in beverage technology?

1 roller bearing

... with xiros conveyor roller for lubrication-free conveyor belts.

2 Belt storage

... with maintenance-free igubal® flange bearings for dry operation.

3 lane adjustment

... with modular and economical Apiro® gearboxes.

*Assumptions for the scaling:

agricultural engineering

- approx. 37,500 machines and implements for soil cultivation and maintenance are produced annually in Germany > 20 % of these are cultivators

- Assumption of 15 years service life and annual production of 500 cultivators with plain bearings

- Average labour costs for DE employees: €45,240 á 2,080 hours per year

Construction machinery

- approx. 91,500 shovel excavators in the EU, > 20 % in DE, > 18,300 shovel excavators with radial bearings

- Assumption of approx. 80.52 tonnes of lubricant

- Average labour costs for DE employees: €45,240 á 2,080 hours per year

Beverage technology

- More than 160 Heineken locations worldwide using conveyor belts, saving approx. 20 tonnes of lubricant

- Average labour costs for DE employees: €45,240 á 2,080 hoursper year