Changer de langue :

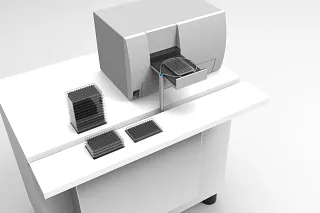

Stockage propre dans la pince économique pour les plaques de microtitration en laboratoire

Peu encombrant, léger : ce préhenseur se compose uniquement d'un fil en acier inoxydable et d'un palier lisse iglidur

Préhenseur Clean Design

La société Ebo Kunze Industriedesign a développé une unité de manipulation à faible coût pour l'automatisation des processus de laboratoire et utilise pour cela des paliers lisses iglidur. Dans un premier temps, un préhenseur traditionnel a été utilisé pour déplacer les plaques d'échantillons.

Comme le préhenseur avait un poids propre élevé par rapport à la charge utile, l'ensemble de l'unité de manipulation devenait lourd. L'objectif était donc de simplifier le mécanisme du préhenseur et de réduire ainsi son poids. Le palier lisse iglidur dans le préhenseur est responsable de deux choses : Le serrage du préhenseur rotatif et le pivotement de l'axe du préhenseur.

Montage compact et simple

Le résultat est très simple : un mètre de fil d'acier inoxydable et un palier lisse suffisent comme préhenseur Clean Design qui, grâce à sa possibilité de pivoter, permet d'économiser toute une direction de mouvement de l'unité de manipulation. Le fil d'acier inoxydable est placé comme une boucle autour de la plaque d'échantillons et serré. La pince tient ainsi fermement la plaque d'échantillons et peut la déplacer d'un point A à un point B. La structure compacte et simple permet à l'unité de manipulation d'être installée sous le niveau de la table de laboratoire.

Cliquez ici pour voir les produits utilisés

Conseil

Je me réjouis par avance de répondre à vos questions

igus® SAS01.49.84.04.04Ecrire un e-mail

Livraison et conseil technique

En personne :

Du lundi au vendredi de 8h à 20h. Le samedi de 8h à 12h à Cologne en Allemagne

En ligne :

24h/24