Changer de langue :

Fibres optiques pour la construction de machines

Transmettre des quantités de données rapidement et sans perturbation

Les exigences techniques en matière d'alimentation en énergie dans la construction de machines et d'installations nécessitent des câbles au fonctionnement sûr. igus®, Cologne, mise ici de plus en plus sur les câbles à fibres optiques en verre, qui permettent de transmettre de très grandes quantités de données tout en augmentant les longueurs de câble. La famille de produits "chainflex® CFLG.2HG" est dès à présent disponible en stock au mètre ou confectionnée avec des connecteurs.

Testé sur 60 000 kilomètres

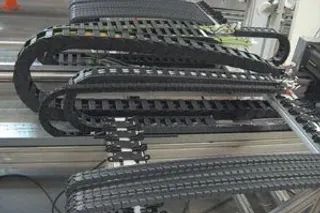

Test d'endurance des fibres optiques dans le laboratoire d'igus®: 60.000 kilomètres parcourus dans la chaîne d'énergie sans incident.

Les câbles à ondes lumineuses en verre de la série CFLG.2HG ont en outre été testés pendant deux ans dans le laboratoire de chaînes énergétiques d'igus®. Une course de 2 m avec un rayon de courbure de seulement 100 mm et une vitesse de 2,5 m/s ont été choisis. Même après plus de 30 millions de mouvements dans la chaîne énergétique - soit 60 000 kilomètres - aucune augmentation de l'amortissement techniquement pertinente n'a été constatée. La fin des tests n'est pas encore en vue.

Cliquez ici pour voir les produits utilisés

Vous trouverez ici d'autres applications intéressantes dans les domaines les plus divers

Conseil

Je me réjouis par avance de répondre à vos questions

igus® SAS01.49.84.04.04Ecrire un e-mail

Livraison et conseil technique

En personne :

Du lundi au vendredi de 8h à 20h. Le samedi de 8h à 12h à Cologne en Allemagne

En ligne :

24h/24